|

|

||||||

|

verpletterender... |

meten=weten |

index | |||||

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

^^^ American thin film specialist Applied Materials had some very catchy solar energy advertisement texts on their Intersolar 2008 stand. There is more truth and justice in these few words than most of those six billion people or the politicians that boast to "represent" them realize... |

Intersolar

2008- 's werelds belangrijkste zonne-energie beurs. Het topje

van de ijsberg

Intersolar 2008 - worlds' most important solar energy fair. Only a tip of the iceberg. |

|

| <<< Entrance of Automatica fair alongside Intersolar (close cooperation due to shared common interests). With robots also used in automated PV-business showing off in a spectacular "European Soccer Dance". The European Cup matches 2008 were running during the trade fair in Switzerland and Austria, hence the welcome surprise... | |

Lesson

in PV-history: Very interesting "mobile PV museum" in the stand

of long-time German PV- and solar thermal component and system

provider, Sunset Energietechnik GmbH (website).

Fascinating insight in development in photovoltaic module technology

showing the "oldtimer" of the most rapidly developing industry

on Earth.

>>> |

|

| <<< One of the old beauties in the Sunset Solar "museum": a SM 144 "Siemens-Interatom" module of around 1984 with 144 (9x16) perfect round, apparently monocrystalline (non-edged) cells with intricate and probably expensive front contact pattern. | |

Basics

at the stand of Germany-based Sunways.

Two so-called "ingots" from which the "wafers" (the basic template

from which all crystalline

silicium

solar

cells are made) are cut with the help of wire saws. Many

vertically integrating companies had similar set-ups to show the

various intermediate "products"

of the rapidly growing solar industry. Which still is dominated

by 90% silicium-based cell production. >>> |

|

| <<< Monocrystalline solar cells are cut from round ingots (picture: right side is "up") that are "pulled" from a hot silicium melt. To minimise space loss in the module, edges are trimmed from the ingot (hence the typical square cells with "rounded corners"). Chinese firm Xi'an Longi Silicon Tech. Ltd is a specialist making very pure, valuable mono Si ingots by applying strong magnetic fields during the "pulling" process. | |

The

huge production of todays' solar industry demands for ever increasing

turn-through times of the delicate solar cells - that are also becoming

thinner (less than 200 µm). Hence, cell-handling machinery becomes

increasingly sophisticated. This is one of several four-armed ultrafast

robots shown on Intersolar, capable of handling solar cells

in a blink of an eye. Robot of Adept in

the stand of automation company SLS

Solar Line Saxony GmbH. >>> |

|

| <<< A very different approach of solar cell production is carried out by Evergreen Solar Inc., which has developed a unique "ribbon-string" process in which a silicium melt is pulled like a soap bubble thin film in between two wires (the composition of which is top secret) through relatively small "ovens" (reddish boxes in the image). Evergreen claims dramatic reduction in process energy and loss of silicium (almost negligable), because the rectangular wafers produced do not need to be cut from an ingot, only separated from each other. This is a huge advantage, and a serious source of cost reduction for the whole cell making process. Shown is a new production line, enabling simultaneous production of 4 "ribbons" of thin wafers. | |

Since

Evergreen is capable of doing away with the big silicium

melt ovens that are easily contaminated, they can also produce

Si cells with narrow nominal power (Wp) tolerance. They deliver

only "plus" tolerance, hence the Wp power of their

modules is always the minimum the customer will get.

Note the typical rectangular

cell-type which is the result from the "ribbon" technology. Although there have been some technological problems

(irregular

surface, polarisation effects), these apparently are overcome.

>>> |

|

| <<< Yet another approach of Si-based module technology is carried out by the Canadian company Day4 Energy Inc. that uses a special contacting and wiring technology with, a.o., a fine square grid "mesh" on the front of the cells. This, according to the producer, results in more (nominal) power per m². The 48 cells containing modules are available in nominal powers of 160-190 Wp. A detail of the fine interconnecting electrical wiring between the multicrystalline 6 inch cells can be viewed HERE. Note the interconnections and the sign of the cell producer: "Q" stands for? (you may only guess once...). | |

|

|

| <<< Californian (Irvine) innovator Lumeta, Inc., showed a very interesting "flat industrial roof" solution with their big monocrystalline PowerPly system using huge, 380 Wp (!) cell plates (plate size 2.4 x 1.2 m., 160 cells each, 31.75 kg.) that are glued to the flat surface of industrial roofs, and that are accompanied by modular DC cabling in protective encasing also glued to the roof. Expensive support structures are not needed, installation time is minimized. | |

PV

comet Sunpower from

the U.S.A. is rapidly developing solutions meant to facilitate

acceptance of

PV for end-consumers. Here their so-called "T10 Rooftile" system

for large industrial flat roofs (tilt app. 13 degrees) that can be

easily interlocked with other modules, and that does not need penetration

of the roof

itself in normal locations. Of course the "tile" contains a beautiful

72-cell high power module of own making using the all back contact

A-300

cells. >>> |

|

| <<< Well-known Japanese Kyocera is upgrading the nominal power for most of their modules. This new multicrystalline specimen, KD210GH-2P, with black cells with 3 distinct "bus bars" already has a rated power of 210 Wp. Nice modules, reliable and long-time producer. Kyocera still has the world record for multicrystalline cell efficiency, 18.5%. An example can be seen HERE. | |

Spanish

producer Vidursolar

S.L. is probably "on the safe side" for their

domestic market if the feed-in regimes for free-field installations

will probably become much lower, and the Spanish market will shift

to building (integrated) PV-systems. Vidursolar makes nice

BIPV "see-through" modules, comparable to the products

of Austrian manufacturer Ertex. >>> |

|

| <<< Possibly the biggest tiger of 'em all, Chinese Suntech Power Co., Ltd., came up with a series of appealing black modules and other products that are specifically meant to reach out to the consumer market and to narrow the gap between the hard core cell producers and the end customers of the silicium-based industry. They also showed an integrated "in-roof" system, based on the MSK Just Roof concept and an integrated "up-roof" system called Quicksnap originally from Akeena Solar. | |

"Just

for aesthetic purposes", said the representative at the

stand of Belgium solar cell producer Photovoltech about

the attractive wavy electrical wiring on these new cells. Photovoltech

also makes a new type of back-contact cells (Maxis BC+) and nowadays

is out of the module business, fully concentrating on cell production.

Customers can't wait, as with all the other cell producers on our

planet... >>> |

|

But... ... there is more under the sun than silicium-based photovoltaics, of course ...

|

|

<<< Possibly "the most wanted of all", at least by big project planners. A model of one of FirstSolar's CdTe thin film modules that has been sold in vast numbers to big projects in Germany and Spain. FirstSolar has already reached 10.5% module efficiency on a commercial basis, shares have skyrocketed, and they have become the biggest player in the thin-film business. Perspectives are good, but there are "prices to pay". The module price has gone up because of everlasting, huge demand, and certain third parties are involved in "fake deals" naming (but not delivering...) these popular modules (Photon, July 2008). |

|

Thin

film modules are not only attractive for big field systems

(to reduce costs and maximize profit from robust feed-in conditions).

They can also be found in the "wanted" port-folio of architects

and other parties involved in Building Integrated PV projects. Here

a photo of a girl combined with a "see-through" thin-film module

by the Taiwanese company NexPower

Technology Corp. The photovoltaic

element consists

of minute rectangular "microcells" spaced evenly to allow (day)light

passing through. >>> |

|

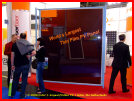

More on thin film Within the strongly growing thin film sector (many start-ups carefully entering the commercial arena with a mind-gobbling spectrum of different techniques and concepts), competition has become stiff between the two big "package dealers". First, Swiss specialist Oerlikon Solar (remarkable absentee on this famous fair...) that has become known for its highly automated process for the mass production of thin film modules, and the promise of CEO Jeannine Sargent to be capable to generate solar electricity on a grid parity basis with thin film modules made on their equipment as soon as 2010 (production cost predicted to be less than € 1/Wp; Photon 5/2008: pp. 82-83). And (2) the American company Applied Materials. While Oerlikon has a fully integrated and highly automated machine package for the production of "conventional" format thin film modules in the order of 1.1 x 1.4 m. (thereby reckoning with the strict labour regulations in Europe: a person may not be allowed to carry or handle big, heavy modules in hazardous roof environments), AM is designing its module equipment machinery to be able to produce "monster modules", in particular for application in free-field installations and in BIPV applications to appeal to architects. Several of the latter could be seen on Intersolar 2008 for the first time. Applied Materials is putting its bet (or: one of its bets) on maximum system and project efficiency by producing as much PV-surface as physically possible in one single module, and then, for example, putting these type of big modules in free-field environments making use of automated glass panel handling machinery on trucks. They showed a video with a "record breaking" Wp/m² installing demonstration. Not all the visitors were convinced that having to deal with monsters like the ones shown below (both made on Applied Materials machinery) was such a good idea, in particular with respect to weight and size of the module (double glass laminate!), and its sensitivity to even mild wind gusts during the installation process. Practice will learn who has the best "bet". Or, viewing the huge demand for any type of good PV module, it will turn out that both big companies will have full order books for their machinery for years to come...

|

|

| <<< Stand of Applied Materials with a monster amorphous thin film module (9% efficiency) made by Signet Solar (using AM equipment) measuring 2.2 x 2.6 = 5.72 m² in surface. One quarter or half this size can also be made. AM claims that 7.5 times less modules are needed for 1 MWp of installed power in free field installations as with conventional thin film modules (think of the popular CdTe types of FirstSolar). These type of installations could become cheaper because of the principle "less labor per Watt", as the company claims. AM has also developed specific "plug and play" junction boxes with an unnamed third party for these kind of modules. Click here for photo. | |

Also

the company Moser

Baer Photo Voltaic Ltd. from New Delhi in what

used to be a "developing" or "third world" nation,

India, and known from the CD production industry, showed off their

alternative. And

boasted

it

is the world's

largest thin film module. It is, however, the same size as the one

from Signet Solar. Of course. It was made on ... their new AM equipment... >>> |

|

| <<< Big modules like the ones mentioned above, pose their own specific problems. For example, preparing and checking the huge glass laminates for production, requires special (and expensive) large equipment capable of handling the huge module sizes. Here a "GPS Perfectscan" from the Austria-based company Lisec Maschinenbau GmbH, that scans big glass laminates for faults and imperfections. | |

Another

"innovation" is the X120

thin

film module made by Inventux

Technologies AG from Berlin. Two basic differences with

the monster modules shown above (apart from size, which is

a "mere" 1.1 x 1.3 = 1.42

m²): (1) they are made up from micromorphous

Si [µSi], (2) the modules are produced on equipment from

... Oerlikon Solar. These thin film beauties will be produced

commercially

as from the

end of

2008. Rated (stabilised) power is 120 Wp. May many thin film

companies follow suit...>>> |

|

| <<< Although some people would refer to flexible solar modules as a "market niche", United Solar Ovonic (short: "UniSolar") has established their speciality for years, sold by a number of companies in various forms, fixed directly to flat industrial hall roofs, or to slanting or even curved zinc roofs on private houses. UniSolar is planning to produce 300 MWp of their triple junction flexible thin-film modules in 2010. A lot of industrial roofs are waiting to be covered... | |

Visitors

having the wrong opinion that there is an invisible borderline between

the "silicium boys" and the "thin-film people" should rethink whilst

visiting the stand of Number One producer of 2007, Silicium King

Q-Cells. This extremely succesful German company is not sitting

on its succes and has developed several "non-Si" off-spring

projects.

Such as its CdTe/CdS daughter Calyxo,

that is on the verge of

commercial

production with modules in a range of 35-65 Wp (IEC certificates

pending). FirstSolar: beware! >>> |

|

| <<< The essence is in the details. Also concerning thin-film technology. One of its specific problems is a reliable fixation of the often thin double-glass laminates onto a bearing frame. Huge problems have occurred by using oversized, non-fitting clamps (leading to breakage). Hence, special clamps have been developed. For detail from the side, click here. Photo from SolarLinea II mounting system for thin-film modules by solar park developer Conergy AG from Hamburg, Germany (via their Epuron offspring). | |

Yet

another developer of thin film technology, Odersun

AG from East Germany makes flexible thin films through

a production process - a combination of CIS (Copper-Indium-diSulfide)

semiconductor (only 1 µm thin) on a supporting copper

band (1 mm thick) that can be further processed for the production

of flexible applications like the one shown at right, or even

glass laminate PV-modules (size flexible upon demand), click

here for an example of such a module. >>> |

|

| <<< Big plans abound in the "solar scene". One of the most impressive is the combined 1 GWp thin film and LCD screen production plant (former) PV champion Sharp (German, click here for Dutch site) from Japan is planning to build in Sakai City. Here a model picture of the facility with a price tag of USD 3.3 billion. This is only one of several GWp projects announced or started up by other big PV companies. Each facility producing a nominal power of a mid-size nuclear plant in PV modules in a few years time. Year after year... | |

"Der Qual der Wahl" (not being able to see the forest through the trees): inverters The inverter market has grown rapidly along with the PV module industry and is on the forefront of technological innovation. The choice for a good inverter has become a difficult task. Off course, with the popular ever bigger growing solar parks, huge inverters of many 100 kilowatts are on the rise.

|

|

Lots

of inverters to choose from nowadays. Here is an assortment

from Wieland

Electric GmbH from Bamberg (FRG). Visible here are consumer-size

inverters (several kilowatts) from, a.o., Mastervolt, Conergy,

Delta, SMA, Diehl AKO, Solutronic, Motech and Pesos. >>> |

|

| <<< Characteristic series of Aurora inverters from the American (Wisconsin) Magnetek company (under the Alternative-Energies.com label) for smaller PV-systems. This lot ranging from 3.0 - 3.6 - 4.2 - 6.0 kilowatt AC, hence more or less the "lesser range" for the major German private market. There are many other brands for decentralized power generation with many more power ranges, up to several hundred kilowatts. | |

Beautiful

Diehl AKO Platinum inverter provided by sales company Matrix

Power Systems GmbH with a maximum of 4.6 kWp of DC power

and max. 4.2 kilowatt of AC power. Extensive datalogging possible

("communication stick" with USB plug, Viewmaster,

Webmaster), display showing actual AC power (graph) and other

data such as money earned (feed-in), CO2 reduced, etc. 5 year

standard guarantuee can be extended to 20 years. One of the

innovations: The production process is free from the use of

the environmentally problematic metal lead (Pb-free). >>> |

|

| <<< Started in the Netherlands, this EVO (originally PSI) series of scalable small inverters plus control unit (right) and wireless monitoring unit (top) could have been the beginning of one hell of a solar adventure for famous Dutch electronics manufacturer Philips. Regrettably things turned out to go in a very different direction. After some problems with a weak component (all replaced in Dutch households), and the collapse of the PV market in the Netherlands, Philips sold the inventory to Steca Elektronik GmbH in Germany, who still has this 300/500 Watt concept in its portfolio. | |

The

final chapter in Philips' solar adventure was a nice 2

kilowatt (AC) inverter that has now been upgraded to

this StecaGrid 2000+ master/slave system with extensive monitoring

facilities. A big shame that this beautiful invention has

been brutally skipped from Dutch electrical engineering history

and that the original developers have not seen their hard

work and succes being put to good use on their home market!

For now the German market may profit from this beautiful

inverter. "We" wish Steca a lot of succes with

it. >>> |

|

| <<< Always nice to see the inside of a good inverter (here one from the Sunny Mini Central series) from market leader SMA, who is rapidly expanding its already monumentous capacity to a possibly staggering 4 Gigawatt nominal power at the end of 2008. The highly successful company will enter the stock market to be able to finance their expansion plans. Top quality made in Germany. Highly facilitated by one of the most robust and intelligent feed-in regimes politicians have ever constructed, based on the world-famous EEG law. | |

Big

solar parks generate demand for huge inverter solutions. This

one, AMC 2500C ("Messe première") from Padcon

GmbH, with two powerblocks generating a total capacity

of a respectable 2.5 Megawatts, is able to feed in directly

into the medium voltage distribution network. A very interesting

tool for independent companies to eat away the fundaments from

the mostly very unhealthy oligopolies in the national electricity

markets. Note the supporting advertisement from American thin

film producer FirstSolar. In recent times, numerous BIG new

solar parks have been built with many tens of thousands of

their highly attractive CdTe modules... >>> |

|

Concentrating solar light While in Freiburg (2007) one of the central themes appeared to be the omnipresence of a staggering array of solar "trackers" (mostly for Si-based PV-modules, and for the biggest part meant to be installed in feed-in attactive, sunny Spain), a considerable number of companies on Intersolar's first presentation in Munich were displaying an array of very interesting "solar concentrators". Not to be mistaken for the also rapidly developing concentrating solar power (CSP) technology, which applies heated fluids and steam for generating electricity in desert-like areas (these are almost always developed at a huge scale to suppress cost price of the output). The concentrators meant here all make use of various kinds of photovoltaic cells on which sunlight is concentrated via mirrors (low concentrating systems, factor in the order of up till 10 "suns") or fresnel lenses or other highly sophisticated lens/optics techniques. With fresnel lenses already almost 400 "suns" amplification has been realized by ISE spin-off Concentrix in practice, but developers are already busy with systems using concentration factors of more than a thousand "suns"... Some sources refer to this approach as CPV (concentrator photovoltaic) systems. Various concepts were shown, all with high potency for delivering as much energy as possible from relative small areas. Because of the concentration factor most of these modules have to be tracked, either on single-axis trackers (lower concentration factor), or on double-axis trackers (high concentration factor). At he bottom-line of this market segment, simple, non-tracked systems are to be found using only static mirrors. Below a few examples of this booming market. An interesting article about this market segment could already be found in the international magazine Sun & Wind Energy 3/2007: pp. 148-155. Somewhat earlier, German top magazine Photon published two articles in issue 4/2006: pp. 51-53.

|

|

| <<< New Si-Con™ 120X CPV module from the British company Silicon CPV plc using 2x2 cm. silicium cells with an efficiency of 18% and a sun concentration factor of 120x on a bidirectional tracker. The company is a spin-off of the Akhter group founded by Prof. Humayun Mughal and claims to reach grid parity in 2010 by their "disruptive" technology, making use of patented prismatic lenses. Shown here is the 48 cell MCPV-48 module with a nominal power of 150 W (measured at 850 W/m² and 60 ºC). Natural ventilation through slits in the broad side of the module. Details: prismatic cell and backside of module. | |

Another

highly interesting approach by the same company is this fascinating

module at even lower concentration factor, the Si-Con™ 4X

module. It has almost the same specifications as the higher concentrating

module shown above and is specifically designed

for rural electrification according to the datasheet for either fixed,

or low-accuracy tracking purposes. Due to simplicity of the module

approach, Silicon CPV claims to outcompete

others by

making cheaper modules. For detail, click

here. >>> |

|

| <<< German company Solar*Tec AG, based in Aschheim, and involved in all three major fields of PV (silicium, thin-film and concentrator technology) showed their high concentrating "3rd generation" 60 W Sol*Con™ module using 144 triple junction cells (cell surface each only 4 mm²) per module and tempered front glass plates with fresnel lenses only 3,2 mm thick. | |

A

spectacular PV concentrator could be seen at the stand of SolFocus,

Inc. from Mountain View in California (U.S.A.). It makes use

of ø 31 cm. metallic parabolic primary mirrors reflecting the sun

onto a small central second (concave) mirror (glued to the glass

plate) that concentrates the sunlight

on a

glass rod that focusses the light onto a 1 mm² III-V type Spectrolab

solar cell (37% eff.) in the centre of the big mirrors. In this module

16 of these

units

are present in one casing. For detail, click

here. SolFocus is trying to translate this interesting

"Cassegrain telescope" concept (original from Ben Gurion Univ. in

Israel) into cheaper full-glass flat plates only 12 mm. thick... >>> |

|

| <<< And yet another, low concentration approach can be seen in this peculiar configuration named Traxle™ from Poulek Solar Ltd. (tracker website: www.solar-trackers.com) making use of single axis trackers, conventional multicrystalline PV modules, and "simple" metallic mirrors (various make-up possible) in between to get more sunlight onto the solar cells. Poulek mentions this specific type a "Tracking ridge concentrator", see their specific concentrator website. | |

PVT becoming succesful? The combination of photovoltaic cell technology and simultaneous warm water production via solar thermal principles has been a major technological challenge because of the very different phyisical demands each technology has on the module buildup. There were however some companies who seem to have progressed in this field. If commercially exploitable, this promises to be an interesting combination for people and institutes not having lots of roof space, but neverthelesse wanting to profit from the sun for the production of solar electricity and hot tap water as well. A good article on the new developments with PVT appeared in German magazine Photon 6/2008: pp. 68-75.

|

|

PVT

modules ("Phototermie") from first time Intersolar guest Solarhybrid

AG from Brilon in Germany. Each "half module" has 42

monocrystalline cells fixed directly under the glass plate,

and somewhat deeper in the modules one can see the characteristic

solar

absorber

comparable to the ones found in many "conventional" thermal collectors.

Maximum solar cell temperature measured: 60,9 º C. The company also

had another novelty, a "Thermogenerator" converting surplus heat

into

electrical

energy. >>> |

|

| <<< Different solution by IDS AG from Zürich (Switzerland): DuoSolar®, a "conventional" 175 Wp monocrystalline PV-module with on the back a "cooling plate" (max. 600 Watt thermal energy) through which heat is drawn away with a liquid system feeding a thermal solar system or heat pump. By varying the water flux, one can optimise the PV-efficiency or the solar thermal efficiency. Click here for a photo from the backside of this interesting PVT module. | |

The outer space Like

in Freiburg, there was a permanent show in open air with a number

of stands. This is the area mostly occupied by the Big Guys,

who install incredible numbers of PV modules in large free field

installations (2007-2008 was one big PV building frenzy in Spain,

before the old Decreto Real will end in September). Big

trackers keep the hormones of the often male visitor running

a little

bit faster.

We remain

children and "toys for the boys", n'est

ce pas?

|

|

Despite

their incredible downfall as a PV company (shares have seriously

fallen in price, managers are restructuring the company),

Conergy AG in

Germany has a very succesfull solar park building branch

(within Epuron

GmbH)

that

delivers high tech solutions for this very demanding market segment.

In the foreground two of the solar trackers in their portfolio. Conergy

is one of few companies having succeeded building a huge PV

plant

(18 MWp near

harbour city Sinan) in South Korea in time before the feed-in regime

in that country regrettably will deteriorate. >>> |

|

| <<< Portion of one of the big tracker systems of Conergy that uses huge linear single axis actuators to move several parallel arrays of PV modules by only one motor. Great attention is given to minimizing wear and tear, so that maintenance of solar parks realized with these trackers can be minimal. Single axis tracking is cheaper than double axis tracking and reduces total Balance Of System costs. Yield increase realized is claimed to be approximately 20%. | |

One

of the biggest "live" trackers was this monster from Sinosol

Technologies GmbH (former: Maxxsolar GmbH), with double axis

tracking technology and carrying 117 monocrystalline modules. The

company claims

to be able to increase the kWh output with maximum 45% as compared

to a fixed installation with a max. capacity of 21,8 kWp. For detail

of the tracking machinery, click

here. >>> |

|

| <<< A behemoth not present in full-scale, but here in a small model, is the enormous S:Wheel® from Bavarian RW Energy GmbH (part of the Rädlinger group). Even on the biggest solar fair in the world, there was no place for a concrete and steel structure 26 meter in diameter (but only 1.8 m. high including modules) and a net weight of 7.500 kg. without modules. Up to 36 kWp can be installed onto one S:Wheel, max. 0.2 kWh/day is consumed by the tracking machinery. In Toledo (Spain) already 30 S:Wheels are running since November 2007. | |

Just another selection From the immense amount of "things to see" and an astonishing series of companies never heard of, Polder PV makes a final selection for you. Of course, only the tip of the iceberg can be shown...

|

|

Relative

novelty of Sanyo, with their remarkable

HIT module series. This powerful 230 Wp module (code: HIP-230HDE1)

has amazing almost hexagonal monocrystalline cells with rounded

corners of the "HIT-type" (instead of cutting off

4 sides from the round

ingot,

Sanyo cuts

off 6 narrower sides, resulting in cells occupying less space

in the module). Sanyo claims an astonishing, high-temperature

resistant cell type with 19.2% efficiency, for the module a respectable

16.6%. For detail of cell click

here. >>> |

|

| <<< Integrating solar cells into, a.o., glass façades for BIPV applications demands creative solutions. Here an example of a plug-and-play "Edge Connector" to be able to position cells far from the edges from the glass laminate or module, still be able to make electrical connections and preventing laborious (and visible) electrical wiring. The connector is visible on top of this model, its prefabricated metal "feet" extend in between the glass laminate towards the contacts of the solar cell (designed for 6" cells). Cooperation project between Tyco Electronics and Solarwatt AG. Delivery of this system as of 2009. | |

Although

the Dutch PV market remains small because of ongoing political shortsightedness

and tear-jerking sabotage by bureaucrats, several companies

make good products

and sell them abroad in solar energy loving countries.

Here the busy stand of ClickFit demonstrating

their light

fixing rail system that has been TÜV certified,

although (fewer and fewer) people still do not believe what their

eyes tell

them. There is also a new, interesting flat roof frame: click

here. Thanx for the hospitality, Vincent and Theo! >>> |

|

| <<< Green, greener, greenst. Why should a roof be an ecological wasteland of concrete, asphalt paper or rooftiles? The Deutscher Dachgärtner Verband e.V. (DDV, "German Roof Gardeners Union") thinks that even with sophisticated PV installations or solar thermal collectors, the roof should remain a living thing. There are many houses in Germany with a good match between nature and high-tech. In addition: natural water storage and insolation for free... | |

There

were several other solutions as the one mentioned under the

Clickfit section above for being able to adjust the angle of

solar panels with minimum adjusting

time.

This nice one, called Tric F, and continuously adjustable from

15

to

60 degrees, with TÜV certification,

is from Germany, Cölbe based Wagner

& Co. It can be used on flat or

slanted roofs, or in free-field arrays. >>> |

|

| <<< Very nice combination of wood and thin film solar strips by German (Neresheim, Baden-Württemberg) company Holz und Solar by Grimmeisen CEKO. Patent is pending. For German text on this system, see this pdf document. For detail photo of the façade system, click here. | |

One

of the most interesting new items on Intersolar 2008 was this Californian

invention, Solmetric's

SunEye™,

with which one can make a photograph with a fish eye lens

and directly obtain detailed

information about shadowing

of the environment on a potential location for a PV-installation.

Having a very user-friendly software interface, this will

become a wanted instrument

within the installation branche. Reviewed in German magazine Photovoltaik

07/2008: pp. 68-69. >>> |

|

| <<< Professional PV-magazine Photon (the German branche) was also present at Intersolar, and... they had a very nice offer for Photon subscribers. They can use for free (as long as subscription is valid) a PHOTON-Control logger using satellite measurements to check the production of their PV-installation. A € 690 Sensorkit is optional with, a.o., a light sensor (SP Lite) made by Kipp & Zonen BV from Delft, NL (click here for detail). Subscribers seem to be in a waiting line for this fascinating offer... | |

World

PV market Number One (2% of total electricity consumption already

covered...) Bavaria, FRG, may have a lot of sun and thousands

of big PV-systems, it has also a minor extra problem: lots of

snow in winter. Deaths and severe injuries have occurred with

people trying to clean their PV-roofs of snow - a very dangerous

undertaking. This company, with the fascinating name Schneerutsch

und futsch GmbH (...), has developed an automatic snow

(and dirt: "Spray-Away") cleaning device for proud

Bavarian many-kWp PV owners wanting to stay on the safe side

and still

having some unspent money on the savings account... >>>. |

|

| <<< Public lighting is consuming large amounts of electricity. Many initiatives are undertaken for alternative lighting concepts, making use of sunlight, accu storage, and low-electricity consuming LEDs. This highly aesthetic, solar electricity-fed 24 Volt LED lamp from Zytech Solar (Zaragoza, Spain) should appeal to many community officials. Zytech is looking for distributors. For detail of the LED lamp click here. | |

SolarWorld AG sponsored beautiful racing car SolarWorld No. 1, designed by Hochschule Bochum was present live on Intersolar 2008. It is covered with multi-junction solar cells (6 m², click here for detail) that are also used in space satellites. On this front, however, the Dutch have been long-time supreme system designers with the continuing successes of the Nuna competitors sponsored by the - still Dutch - NUON utility holding. >>> |

|

<<< To end this "minute" Intersolar presentation, an "outlyer" on

this PV-dominated solar fair (not mentioned the solar thermal

section, for which I did not have time...). Schott

Solar is also involved in yet another booming solar branch,

that of the Concentrating Solar (thermal) Power, CSP. German

Schott earns a lot of money producing the vacuum tubes that

are the heart of the huge parabolic trough plants built in,

e.g., U.S.A. and Spain, and soon in other sunshine-flooded

countries as well. |

|

Referenties/references

(More about Intersolar 2008 and its novelties)

Photon 6/2008 (June): pp. 99-146

Photon International 6/2008 (June): pp. 37-85

Photon

7/2008 (July): pp. 72-75

Photovoltaik 07/2008: pp. 32-44

photo

page:

http://www.intersolar.de/index.php?id=39&L=1

Polder

PV's IS 2008"special": een excursie

naar het zonnedak 30. September 2007, the Solarenergieförderverein Bayern e.V. (SEV-Bayern) celebrated their 10-year existence. This non-profit organisation was set up by - then flourishing - Siemens Solar and old public utility company Bayernwerk (later under the E.ON flag) when they realized world's first huge solar roof plant, the > 1 MWp PV-system on the curved roofs of the first halls of the Neue Messe, "München-Riem", built on the premises of the old Riem airport. This big installation was coupled to the net on November 19, 1997 while the actual installation had only begun in August of the same year. The initiators wanted the proceeds (under the then valid feed-in regime, later replaced by the EEG feed-in law) of the installation being used for the promotion of solar energy. This has been the goal of the SEV-Bayern, who has, among many other things, published several (downloadable) brochures about solar energy, organized competitions on PV architecture, BIPV, and did a lot of promotion work, for example for PV on schools since these pioneering years of large scale implementation of photovoltaic electricity in the built environment. The 1 MWp project was not the end of it, however. More halls were present or even built at the Neue Messe, and thus, more opportunities were created to extend the PV-array. This was done in a new, separate MWp project by the independent PV-project planner Phönix Sonnenstrom AG, since June 2007 known as Phoenix Solar AG. Later still, even the parking garage at the NW of the Messe complex, was covered with solar panels, forming worlds largest test array for different types of PV-modules. At Intersolar 2008, the SEV-Bayern made it possible to visit their (first-built) part of the gigantic solar roof on the Messe halls three times a day. I was lucky having let one particular dark and wet hour pass by (it was rather variable wheather during Intersolar, sun rapidly followed by strong showers), and was able to visit the roof in the sunny next shift. From the excursion balcony, restricted to a load of visitors already streched to the limit during the fair, one had some interesting views on only a fraction of the huge system (the Messe halls are not adjacent but widely spaced). You will find some photographs of the solar roof(s) on München's Neue Messe, with a few nice "shots" from space (Virtual Earth™) also including the huge PV-system on the parking garage of the premises. Bayern (Bavaria) is leading the world in realized big building-associated PV projects. München-Riem is only one of the hot-spots of solar development and well-established multi-functional use of building roofs. The photo section ends with some technical data of the systems built and reference links. I want to thank the SEV-Bayern for having made possible this unique excursion, a nice bonus on top of an already "gelungene" Intersolar 2008, for which the Fair Organisation is to be congratulated!

|

|||||||||

| <<< Looking eastward from the excursion platform in between halls B4 and B5, in the direction of the Messeturm, one already gets an impression of the extent of the huge, south-oriented PV-arrays on the slightly curved huge halls of the Messegelände (foreground: B5, B6 lying behind that hall). Details: array foreground (hall B5) and small section of array on hall B6 in the background. Note: the arrays on the "B" halls are part of the - oldest - Siemens 1 MWp system. | |||||||||

Looking

in a direction slightly north from west, onto part of the

PV-arrays on hall B4. Faintly visible, slightly to the right of the

reddish, old control tower of the former Riem airport, one can see,

on the horizon, the very thin, needle-like TV tower on the premises

of the Olympia park in the

NNE part of Munich. For detail of section left of the old control tower

(roof of hall B4), click

here. >>> |

|

||||||||

| <<< Detail of photo shown above, hall B4, most northern part (right section of previous photo), against a backdrop of what possibly is the "Heizkraftwerk Nord" in Unterföhring (NE Münich). Hall C3, at the back, still lacking solar PV arrays. | |||||||||

Detail

of one of the DC collector cables (DC feed from 4 different arrays)

on the west side of the roof of hall B5 running to the left, where

it

is led

into

the

inside

of the

roof

towards

the

inverters via 4 separate waterproof seals. >>> |

|

||||||||

| <<< Portion of the arrays on the west half of hall A5 (the Phönix Sonnenstrom system), looking approximately in a direction east of south. Hence, one is facing the backside of the modules, being able to see the construction of the frames. For a detail of part of these arrays showing the DC-cabling and frame construction, click here. On the right side of that photo one can clearly see that also these modules are frameless. | |||||||||

Also

on the excursion look-out an example of the module type for the first

1 MWp system is to be seen. It is a - for that time - very

powerful Siemens module having 14x6 = 84 monocrystalline cells

and a module

efficiency of 13%. It has no frame to minimize load on the roofing

structure.Therefore, broad "thin module" clamps were already used

to fix the modules on the frames. Hall A5 with part of the Phönix system

in the background. >>> |

|

||||||||

Some final surprises After Google™ Earth gained momentum with their nice satellite pictures from planet Earth, Microsoft could not sit and wait, of course. They developed Virtual Earth™ instead. It has some powerful options, such as detailed photographs from some locations in a bird eye view. Luckily, Neue Messe in Munich is one of that locations. It gives an extra "dimension" on the pictures already shown on this webpage. The pictures below are from Microsoft Virtual Earth™ and were "discovered" earlier in 2008, when I was preparing for my Mega PV Radtour and the visit to Intersolar 2008 presented on this page. Only recently I found the source for the fascinating system on the parking garage:

|

|||||||||

Technical data of the solar systems on Münchens Neue Messe at the former Riem airport premises:

(1) "Solardach München-Riem" [E.ON/Siemens installation, "B" hall series]

(source: brochure "10 Jahre Engagement für Erneuerbare Energien" - SEV-Bayern e.V.)

![]() Investment

app. 7 billion Euro (app. € 6,89/Wp), 50% E.ON Energie, 20% Bavarian

Ministry of Economy, Infrastructure,

Traffic and Technology, 10% each for Siemens, Stadtwerke München (local

utility), and State Ministry

for Education and Research.

Investment

app. 7 billion Euro (app. € 6,89/Wp), 50% E.ON Energie, 20% Bavarian

Ministry of Economy, Infrastructure,

Traffic and Technology, 10% each for Siemens, Stadtwerke München (local

utility), and State Ministry

for Education and Research.

![]() Net

coupling November 19, 1997

Net

coupling November 19, 1997

![]() 1,016

MWp nominal power

1,016

MWp nominal power

![]() 7.812

frameless Siemens SM 130-L monocrystalline modules of 130 Wp each,

15% cell effiiciency, 13% module efficiency (both: STC)

7.812

frameless Siemens SM 130-L monocrystalline modules of 130 Wp each,

15% cell effiiciency, 13% module efficiency (both: STC)

![]() 84

cells/module, total 656.208 cells

84

cells/module, total 656.208 cells

![]() Total

surface of modules: 7.916 m²

Total

surface of modules: 7.916 m²

![]() Total

roof surface used for PV-system: 38.100 m²

Total

roof surface used for PV-system: 38.100 m²

![]() Orientation

South (azimuth 180º), tilt angle 28º

Orientation

South (azimuth 180º), tilt angle 28º

![]() Inverter:

3 Siemens 330 kVA inverter originally, replaced by 394 kVA inverters

during retrofit in 2007 (DC cabling

split, communication technology, inverter concept)

Inverter:

3 Siemens 330 kVA inverter originally, replaced by 394 kVA inverters

during retrofit in 2007 (DC cabling

split, communication technology, inverter concept)

![]() Net

feed-in: into the 20 kV net of Neue Messe complex

Net

feed-in: into the 20 kV net of Neue Messe complex

![]() Normalized

yield: 1.000 hours/year ("Vollaststunden", kWh/kWp.year). According to

SEV Bayern brochure average

for 1998-2006 was 979 kWh/kWp.year

Normalized

yield: 1.000 hours/year ("Vollaststunden", kWh/kWp.year). According to

SEV Bayern brochure average

for 1998-2006 was 979 kWh/kWp.year

![]() Performance

ratio: best in 2004, 80,6%

Performance

ratio: best in 2004, 80,6%

![]() Yield:

app. 1 billion kWh (1 GWh)/year, that is app. 4% of total consumption

of the Messe complex. Table in SEV Bayern's

brochure gives average of 994 MWh/year for 1998-2006)

Yield:

app. 1 billion kWh (1 GWh)/year, that is app. 4% of total consumption

of the Messe complex. Table in SEV Bayern's

brochure gives average of 994 MWh/year for 1998-2006)

![]() CO2

production eliminated: app. 650 ton/year

CO2

production eliminated: app. 650 ton/year

![]() Fixed

feed-in tariff as of enhancement by EEG: € 0,506/kWh

Fixed

feed-in tariff as of enhancement by EEG: € 0,506/kWh

![]() Proceeds

from feed-in used via SEV-Bayern for the promotion of solar energy

Proceeds

from feed-in used via SEV-Bayern for the promotion of solar energy

![]() Much

more and actualized info on SEV-Bayern website:

http://www.sev-bayern.de/index.php?entryid=14

Much

more and actualized info on SEV-Bayern website:

http://www.sev-bayern.de/index.php?entryid=14

(source: website Phoenix Solar and linked pdf file)

![]() Investment

app. 5,5 billion Euro (app. € 5,20/Wp), Phoenix Energy Investments,

financed as 6 separate so-called Bürgerbeteiligungsanlagen (financing

projects by citizens, presumably 1 hall roof each) via Phoenix Solar

FondsVerwaltung

GmbH & Co.KG. Former partners of the

first "Siemens" installation, as well as Shell Solar GmbH and the

Messe München were

also involved in this second

megaproject.

Investment

app. 5,5 billion Euro (app. € 5,20/Wp), Phoenix Energy Investments,

financed as 6 separate so-called Bürgerbeteiligungsanlagen (financing

projects by citizens, presumably 1 hall roof each) via Phoenix Solar

FondsVerwaltung

GmbH & Co.KG. Former partners of the

first "Siemens" installation, as well as Shell Solar GmbH and the

Messe München were

also involved in this second

megaproject.

![]() Net

coupling/installation 2002. Record breaking installation time in 6

weeks...

Net

coupling/installation 2002. Record breaking installation time in 6

weeks...

![]() 1,058

MWp nominal power

1,058

MWp nominal power

![]() 7.560

frameless Siemens Sp 140 (PowerMax®) monocrystalline modules of

140 Wp each, possibly Shell Solar?

7.560

frameless Siemens Sp 140 (PowerMax®) monocrystalline modules of

140 Wp each, possibly Shell Solar?

![]() 72

cells/module, total 544.320 cells

72

cells/module, total 544.320 cells

![]() Total

surface of modules: 9.966 m²

Total

surface of modules: 9.966 m²

![]() Orientation

South (azimuth 180º), tilt angle 22º

Orientation

South (azimuth 180º), tilt angle 22º

![]() Kalzip fixation system to ribbed metal roof (now part of Corus)

Kalzip fixation system to ribbed metal roof (now part of Corus)

![]() Inverter:

5 Siemens Sinvert 200 kVA

Inverter:

5 Siemens Sinvert 200 kVA

![]() Net

feed-in: presumably also into the 20 kV net of Neue Messe complex

Net

feed-in: presumably also into the 20 kV net of Neue Messe complex

![]() Normalized

yield: 965 kWh/kWp.year

Normalized

yield: 965 kWh/kWp.year

![]() Yield:

1.021.000 kWh/year (according to Phoenix 10% above the expected yield)

Yield:

1.021.000 kWh/year (according to Phoenix 10% above the expected yield)

![]() CO2

production eliminated: 986 ton/year [BMU AGEE]

CO2

production eliminated: 986 ton/year [BMU AGEE]

![]() Fixed

feed-in tariff as of 2002: € 0,481/kWh, 20 years long

Fixed

feed-in tariff as of 2002: € 0,481/kWh, 20 years long

![]() Resulting

annual financial yield: app. € 477.000/year

Resulting

annual financial yield: app. € 477.000/year

(3) "Park Deck Messe München - PV Enlargement test PV-plant/Solarstrom Testfeld" on Parkhaus West flat roof (530 m. above sea-level)

This plant is part of the EU-subsidized "PV Enlargement" project in 10 European countries, in which a grand total of 1,218 kWp of "highly cost-effective or very innovative PV technologies" is demonstrated "for increasing public awareness about and visibility of PV solar electricity", as is stated on the homepage of this project. Which is financed via the 5th framework programme of the European Commission, DG-TREN. It claims to be the worlds largest test field for PV module technology comparison.

(sources: Messe München website and pages on website of PV Enlargement project)

![]() 655

kWp nominal power in total according to Messe München site (398,7

kWp is mentioned on the PV Enlargement site, but the specific page

linked below is

dated 04.05.2007.

It is possible that then only part of the actual system was installed)

655

kWp nominal power in total according to Messe München site (398,7

kWp is mentioned on the PV Enlargement site, but the specific page

linked below is

dated 04.05.2007.

It is possible that then only part of the actual system was installed)

![]() Orientation:

south, tilt 27 degrees

Orientation:

south, tilt 27 degrees

![]() Net

coupled in 2003-2004 (thin film), last crystalline technology followed

in 2005

Net

coupled in 2003-2004 (thin film), last crystalline technology followed

in 2005

![]() Nominal

module power between 55 and 220 Wp

Nominal

module power between 55 and 220 Wp

![]() Many

different module types with comparison between large scale thin-film

technologies (2x CIS; 1x aSi; 1x CdT; 1x

HIT) with crystalline technology (mono- and polycrystalline Si). 11

different PV-technologies are included, the smallest

array having a nominal (total) power of 9 kWp, the largest 61 kWp

Many

different module types with comparison between large scale thin-film

technologies (2x CIS; 1x aSi; 1x CdT; 1x

HIT) with crystalline technology (mono- and polycrystalline Si). 11

different PV-technologies are included, the smallest

array having a nominal (total) power of 9 kWp, the largest 61 kWp

![]() Also:

large-scale comparison of 5 different inverter technologies

Also:

large-scale comparison of 5 different inverter technologies

![]() Taking

into account the reported "grand" total of 21.900 modules

on the Messe München site, this test system should

consist of 21.900 - 7.812 (Siemens

system) - 7.560 (Phönix system) = 6.528 modules

Taking

into account the reported "grand" total of 21.900 modules

on the Messe München site, this test system should

consist of 21.900 - 7.812 (Siemens

system) - 7.560 (Phönix system) = 6.528 modules

![]() Total

surface of roof available on Neue Messe: 149.000 m², total surface

(incl. Parkhaus) used for PV: 75.000 m²

Total

surface of roof available on Neue Messe: 149.000 m², total surface

(incl. Parkhaus) used for PV: 75.000 m²

More information about this very interesting test plant:

http://p12892.typo3server.info/64.0.html (with

photo's and detailed information about the module types involved)

http://p12892.typo3server.info/uploads/media/PVSEC21-WIP.pdf (scientific

report with results of comparison, presented september 2006 at PVSEC21)

Further info of Messe roof PV-systems:

http://tuprints.ulb.tu-darmstadt.de/290/12/Anhang_B11_B13.pdf (extensive

technical description and analysis of 1st Siemens MWp system)

http://www.messe-muenchen.de/de/Home/cn/Presse/26092/26094/26511 (press

release Messe München after installation 2nd Phönix MWp system)

© August 9, 2008 Peter J. Segaar/Polder PV, Leiden, the Netherlands

|